Heat exchangers made with round copper tubes and plate fins are the workhorses of the HVACR industry. They are referred to simply as tube-fin (T-F) heat exchangers. The plate fins can be made of copper or aluminum.

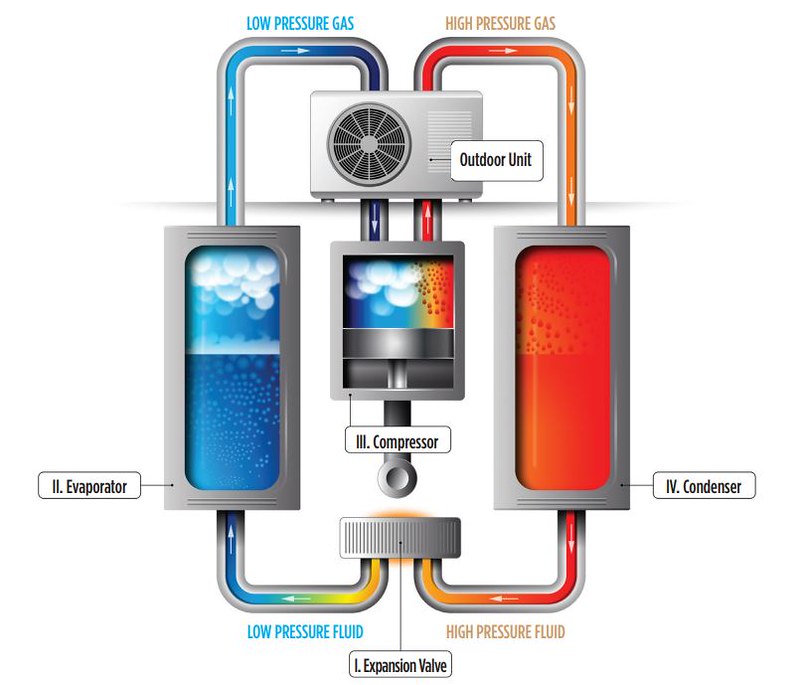

T-F heat exchangers can serve as condenser coils, in which case they cool the compressed refrigerant and release heat into the ambient air. In other words, the heat flows out from the condenser or gas cooler.

Alternatively, T-F heat exchangers can be used as evaporators, in which case the heat flows into the heat exchanger. The refrigerant expands and “boils” inside the tubes, changing from a liquid to a vapor, picking up heat from the ambient air.

T-F heat exchangers are extremely efficient either way. They are durable, strong and corrosion resistant, too. That’s why they are the preferred technology for the whole gamut of products based on the vapor compression cycle. Let’s take a closer look at some of the products and equipment that use T-F heat exchangers.

Residential HVAC

Room air conditioners (RACs) offer inexpensive cooling for renters and homeowners throughout North America. It has had a major effect on the demographics of populations in North America. Low-cost RAC appliances are made in volume.

Copper round tubes are widely used in RAC evaporators, including window units of various capacities as well as the evaporator component of split systems.

Since RACs are made in volume, OEM appliance manufacturers have aggressively pursued cost and materials savings. They have invested in the necessary research and manufacturing equipment to make these units as efficient as possible. It is no surprise therefore that smaller diameter copper tubes were first used in RACs.

As a result of years of research, the outer diameter of the copper tubes in T-F heat exchangers was gradually reduced from 9.32 mm (3/8 in.) to 7 mm and to 5 mm. Today’s copper tube technology was born in the manufacture of RACs, including the fabrication of precision copper tubes and the heat-exchanger coils made from them. Inner grooves were first introduced in RACs to squeeze out greater heat exchange capacity from evaporators and condensers, which contributed to improved system performance and system efficiency, i.e., higher EER and SEER values.

As smaller-diameter, inner-grooved copper tubes became available, this new technology was applied to the C-shaped outdoor condensers, which are widely used in homes throughout the USA; as well as in the A-coil evaporators, which cool the air circulated through homes in ducted systems.

Commercial HVAC

The technology has also been adapted for use in packaged terminal ACs (PTACs) for light commercial applications as well as large commercial rooftop condensers for office buildings. Most major coil makers in the U.S. and internationally offer round tube plate fin (RTPF) coils for commercial and industrial applications, using a variety of refrigerants, including low GWP (R32) and ultralow GWP (HFO blends and natural) refrigerants. Commercial equipment includes rooftop condensers with heat-transfer capacities ranging from a few tons to hundreds of tons. Copper tube diameters in commercial-sized condensers today range from conventional diameters to diameters as small as 5 mm. These heat exchangers made with copper tubes are the industry standard and are renowned for their durability and resistance to corrosion.

Refrigeration Equipment

As concerns about climate change grew around the turn of the millennium, the high global warning potential of hydrofluorocarbon (HFC) refrigerants raised alarms, and the search for alternative refrigerants began in earnest. Hydrofluoroolefins (HFOs) were developed as "fourth generation" refrigerants with GWPs thousands of times less than the GWP of typical HFCs. Also, hydrocarbons such as propane (R290) and isobutane (R600A) were candidate natural refrigerants with ultralow GWP and excellent thermodynamic properties.

The high cost of HFOs and the flammability of hydrocarbons motivated the development of condensers and evaporators with smaller tube diameters to reduce refrigerant charge. The technology was already developed for air conditioners, and soon it also was adapted for use in bottle coolers and cold display cases such as are commonly used in convenience stores.

These applications have been subject to refrigerant charge limitations, which favored the use of smaller diameter copper tubes. Copper tubes not only provided the reliability and durability necessary for use with flammable refrigerants but also the smaller diameter tubes reduced the amount of charge required. The success of propane (R290) would not have occurred without the refrigerant charge reductions possible using smaller diameter copper tubes.

Copper’s Role in Emerging Technologies

One of the ironies of nature is that carbon dioxide as a waste product of combustion is also an excellent refrigerant. Now known as R744, carbon dioxide is the reference value for GWP and has an ultralow GWP value equal to 1. R744 also lends itself well to efficient refrigeration and heating systems. Once again, smaller diameter copper tubes are proving to be especially well suited for the heat exchangers typically employed in such systems. Above about 87 °F, R744 does not condense into a liquid but rather it behaves as a supercritical fluid. This fluid can flow easily through smaller diameter copper tubes with little resistance. The pressures of the compressed CO2 supercritical fluid are enormous. Pressures greater than 100 atmospheres are typical for an R744 gas cooler. Smaller diameter tubes can withstand higher pressures without bursting compared to larger diameter tubes with the same tube-wall thickness. Also, a high strength copper alloy (C19400, also known as CuFe2P).

For many reasons, copper T-F coils are uniquely well suited to the next generation of heat pumps and air conditioners. Exciting new technologies, products and systems are under development, taking full advantage of the many benefits of copper. These product trends are covered in the Technology Trends in Support of Sustainability section.

Case Studies:

- Computer Simulations with OTS CoilDesigner Software

- A New Heat Exchanger Geometry for Next Condenser Generation with Ultra Low Refrigerant Charge

- Experimental Research for Lowering Refrigerant Charge

- CDA Webinar – Transitioning to Alternative Refrigerants: Implications for Heat Exchanger Design

- Design of 5 mm Copper Tube Heat Exchangers for Display Cabinets with R404A

- Copper vs Aluminum: Dispelling Misinformation about Coil Corrosion

- CDA Heat Pump

- Less is More: Why Smaller Diameter Copper Tubes are More Efficient

- Impact on Performance with Inner-Groove in Copper Tube

- Improving Heat Pump System Performance through Small-Diameter Copper Tube and Design Optimization: A Case Study with Whirlpool Corporation